Bevel Gear Solutions for Angular Motion Control

Built for Efficiency, Precision, and Durability

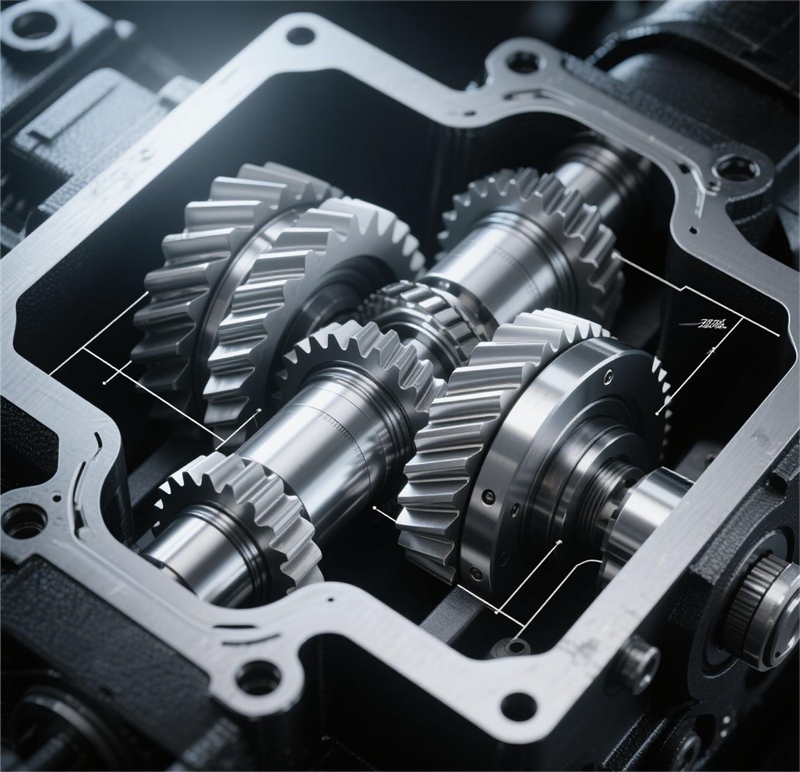

Understanding Bevel Gears

Bevel gears are a type of gear with conical geometry, used to transmit power between intersecting shafts—typically at 90 degrees. At Telin, we manufacture precision-machined bevel gears in various configurations to serve automation, machinery, and heavy equipment applications.

With ISO9001-certified processes, advanced CNC gear cutting, and custom engineering capabilities, we ensure smooth, quiet, and efficient angular power transmission in every product we deliver.

Product Center

Welcome to Telin Machinery — your trusted partner in precision transmission components. We are an enterprise committed to delivering high-quality gear solutions for global industrial applications.

At Telin, we understand that the reliability, accuracy, and durability of mechanical components are critical to keeping your machines running smoothly. That’s why we specialize in the design and manufacturing of standard and custom gears, including spur gears, bevel gears, helical gears, racks, and sprockets — all engineered to meet demanding performance needs across various industries.

Explore our product center and discover gear solutions that drive your machines with precision and efficiency.

Factors Affecting Bevel Gear

Smooth & Quiet Operation: Spiral teeth allow gradual tooth engagement, minimizing noise and vibration.

High Load Capacity: Optimized geometry increases surface contact, allowing greater torque transmission.

Precision Manufacturing: CNC milled and ground for excellent concentricity and tooth accuracy.

Material Versatility: Available in hardened steel, stainless steel, or brass for different load conditions.

Custom Configurations: Shaft angle, module, number of teeth, and bore options can be tailored to your needs.

Corrosion Resistance (Optional): Surface treatments like black oxide or nitriding available

Technical Specifications

Spiral Bevel Gear

Applications of bevel gears

CNC Machining Centers

In high-precision CNC machining systems, spiral bevel gears enable smooth and accurate angular power transfer between intersecting shafts, especially in compact spindle or toolhead assemblies. Their curved tooth design ensures minimal vibration and precise positioning during high-speed operation.

Industrial Gearboxes & Reducers

Spiral bevel gears are widely used in industrial gearboxes to redirect torque at a 90-degree angle with high efficiency. Their ability to handle large loads with quiet operation makes them ideal for heavy-duty reducers in manufacturing, material handling, and automation equipment.

Agricultural Transmission Systems

From tractors to harvesters, spiral bevel gears are essential in agricultural machinery for delivering angular motion in steering mechanisms, axles, and rotary drives. Their robust build ensures durability in dusty, high-load, and vibration-prone environments.

Frequently Asked Questions (FAQ)

Q1: Can I order custom gears based on my drawings or samples?

Q2: What types of gears do you manufacture?

Q3: What materials are available for your gears?

Q4: Do you have ISO or quality certifications?

Q5: What is your typical lead time?

Q6: Can you provide samples before mass production?

Q7: Do you offer surface treatments or heat treatments?

Q8: Where do you ship from, and what shipping methods are available?

Related Blogs

-

When it comes to manufacturing high-performance gears, selecting the right material is critical for achieving optimal performance, longevity, and efficiency. Whether you are working with helical gears, bevel gears, or even spur gears, the material you choose can significantly impact the overall functionality and durability of the gears. But with so many options available, how do you determine which material is best suited for your gears?Latest News

When it comes to manufacturing high-performance gears, selecting the right material is critical for achieving optimal performance, longevity, and efficiency. Whether you are working with helical gears, bevel gears, or even spur gears, the material you choose can significantly impact the overall functionality and durability of the gears. But with so many options available, how do you determine which material is best suited for your gears?Latest News -

Have you ever wondered how machines transmit power between shafts at varying angles? The answer lies in bevel gears. These essential components play a crucial role in mechanical systems by changing the direction of rotational motion between two intersecting shafts. Whether it's in automotive gear systems, industrial machinery, or power transmission devices, bevel gears ensure efficient power transfer with minimal friction and wear.Latest News

Have you ever wondered how machines transmit power between shafts at varying angles? The answer lies in bevel gears. These essential components play a crucial role in mechanical systems by changing the direction of rotational motion between two intersecting shafts. Whether it's in automotive gear systems, industrial machinery, or power transmission devices, bevel gears ensure efficient power transfer with minimal friction and wear.Latest News -

In the world of mechanical engineering, choosing the right gear is crucial for the efficiency and reliability of machinery. Whether it's for high-speed systems or heavy-duty applications, gears play a significant role in transmitting power and motion between different mechanical components.Latest News

In the world of mechanical engineering, choosing the right gear is crucial for the efficiency and reliability of machinery. Whether it's for high-speed systems or heavy-duty applications, gears play a significant role in transmitting power and motion between different mechanical components.Latest News

Keep in touch with us

Tel:+86-02084787929

E-mail:sales@gztelink.com

Address:No.3 building, No. 8 Xihuan Road, Shilou Town, Panyu District, Guangzhou, China.