Explore Our Pulleys, Our comprehensive range of V-Belt Pulleys is designed to meet diverse industrial needs. We offer various categories including standard industrial pulleys, heavy-duty agricultural pulleys, precision automotive pulleys, and custom-designed options for specialized machinery. Each category is crafted with precision to ensure optimal performance, durability, and compatibility with different V-belt types and drive systems. Whether you require pulleys for light-duty applications or robust, high-torque environments, our selection provides reliable solutions tailored to your specific requirements. Explore our categories to find the perfect fit for your equipment, ensuring efficient power transmission and prolonged operational life.

Advantage

Optimal Performance

Our V-Belt Pulleys are engineered for optimal performance, ensuring smooth and efficient power transmission in various applications. Precision manufacturing guarantees accurate alignment and consistent belt contact, minimizing slippage and maximizing energy transfer. This results in quieter operation, reduced wear on both the pulley and the belt, and ultimately, enhanced equipment efficiency. We utilize high-quality materials and advanced production techniques to maintain tight tolerances, ensuring that each pulley delivers reliable performance under demanding conditions, contributing to the overall productivity and longevity of your machinery.

Durable Construction

Our V-Belt Pulleys employ robust materials such as high-grade cast iron or steel, chosen for their strength, wear resistance, and ability to handle high loads and operating temperatures. The precise machining and quality finishing protect against corrosion and damage, extending the service life of the pulleys significantly. This durability translates to reduced maintenance needs, lower replacement costs, and increased uptime for your equipment, making our pulleys a cost-effective solution for demanding power transmission applications.

Technical Specifications

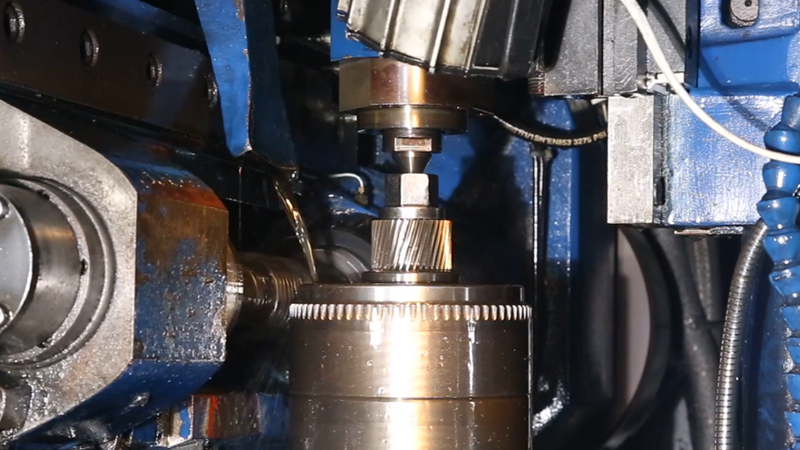

V-Belt Pulleys are available in various configurations to suit different requirements, primarily categorized by their groove design and bore specifications.

Groove Configuration

Bore and Mounting

Application

Industrial Machinery

V-Belt Pulleys are fundamental components in a wide array of industrial machinery, driving everything from conveyor systems and pumps to mixers and compressors. Their ability to transmit power efficiently between rotating shafts makes them indispensable for automating processes and powering heavy-duty equipment in manufacturing plants, processing facilities, and warehouses.

Agricultural Equipment

In the demanding environment of agriculture, V-Belt Pulleys power essential equipment like irrigation pumps, threshers, and harvesters. They are crucial for transmitting the engine’s power to various working parts, enabling efficient field operations. Our durable pulleys are designed to withstand dust, dirt, and heavy vibrations common in agricultural settings, ensuring reliable performance season after season and helping farmers maintain productivity.

Material Handling Systems

Material handling systems, including belt conveyors and elevators, rely heavily on V-Belt Pulleys for continuous and efficient movement of goods. These pulleys ensure smooth belt tracking and consistent speed, which is vital for sorting, transporting, and processing materials in logistics centers, distribution hubs, and production lines.

Light Automotive & Generators

While often associated with heavy industry, V-Belt Pulleys also play a role in smaller-scale applications like powering auxiliary components in some light automotive systems and driving generators for backup power or remote operations. They provide a simple yet effective means of transferring rotational energy to alternators, water pumps, or generator rotors, ensuring these essential functions operate reliably when needed.

FAQs

Q1: What materials are V-Belt Pulleys made from?

Q2: How do I choose the right V-Belt Pulley size?

Q3: Do you offer custom V-Belt Pulleys?

Q4: What materials are commonly used to make V-Belt Pulleys?

Related Blogs

-

V-belt pulleys are a fundamental part of power transmission systems used in a wide range of mechanical and industrial equipment. From HVAC systems and automotive engines to manufacturing machines and agricultural tools, V-belt pulleys work in tandem with belts to transmit power efficiently between shafts.Latest News

V-belt pulleys are a fundamental part of power transmission systems used in a wide range of mechanical and industrial equipment. From HVAC systems and automotive engines to manufacturing machines and agricultural tools, V-belt pulleys work in tandem with belts to transmit power efficiently between shafts.Latest News -

In the world of mechanical power transmission, the V-belt pulley plays a pivotal role in transferring rotational motion between shafts. While its design and geometry are essential, the material of the pulley significantly impacts its performance, durability, and suitability for specific applications.Latest News

In the world of mechanical power transmission, the V-belt pulley plays a pivotal role in transferring rotational motion between shafts. While its design and geometry are essential, the material of the pulley significantly impacts its performance, durability, and suitability for specific applications.Latest News