- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

Changing the size of your v belt pulley can make a big difference in your v belt setup. When you replace a v belt pulley with a larger one, you’ll notice the speed ratio changes immediately. A v belt pulley works by using a v belt to transfer power from one shaft to another, ensuring your machines operate smoothly. By selecting the right v belt pulley, you have control over both speed and torque. Here’s how the size of a v belt pulley can affect real-world performance:

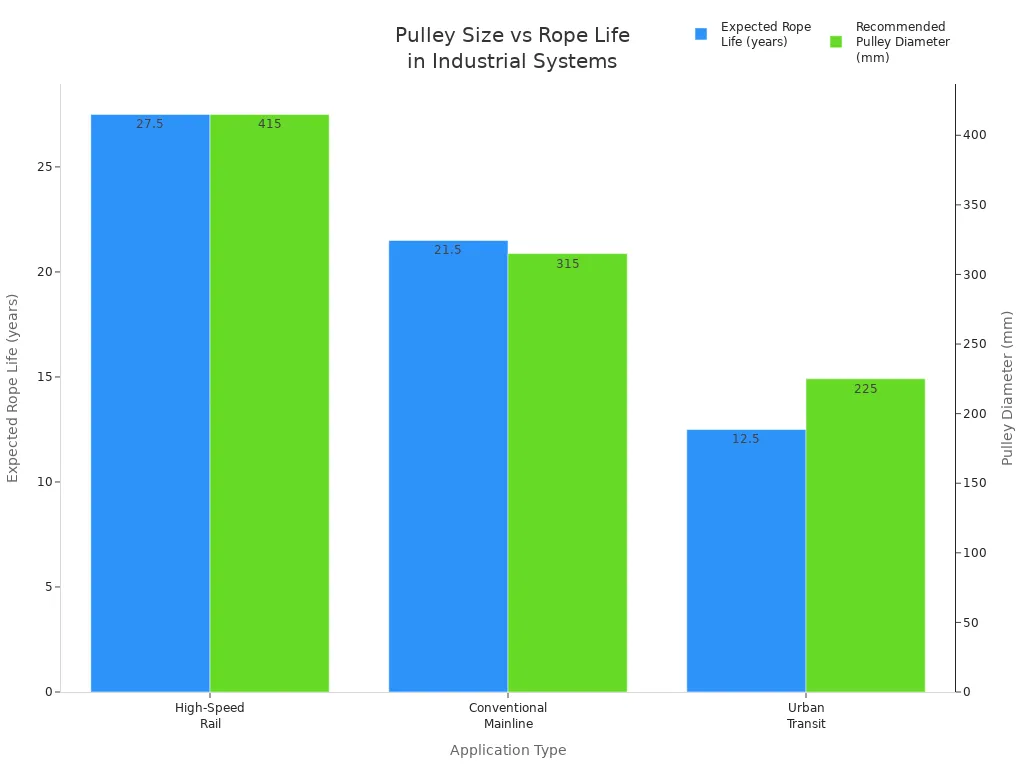

For instance, if your motor v belt pulley is 3 inches and your driven v belt pulley is 6 inches, the driven speed is reduced by half. Using a larger v belt pulley can improve efficiency and increase rope life, which is especially important in heavy-duty v belt pulley applications.

Changing pulley size changes how fast a machine goes and how strong it is. Larger pulleys make machines go slower but give more strength. Smaller pulleys make machines go faster but have less strength.

The V-shaped groove in pulleys helps the belt hold on tight. This makes power move better and stops slipping. It helps the machine work better.

Use the speed ratio formula to find out how fast the driven pulley spins. Driven speed equals driver speed times driver diameter, divided by driven diameter.

Pick pulley size based on what your machine needs. Use larger pulleys for heavy things and more power. Use smaller pulleys for more speed and small spaces.

Check pulley alignment, belt tightness, and wear often. This keeps your system working well. It stops slipping and helps your V belt and pulleys last longer.

When you look at a v belt pulley, you see a simple but powerful tool for mechanical power transmission. A v belt pulley is a round wheel with a V-shaped groove around its edge. This groove matches the shape of a v-belt, which helps the belt stay in place and grip the pulley tightly. You find v belt pulleys in many sizes and types, such as standard, variable speed, and step pulleys. Each type fits different needs in power transmission. Engineering handbooks say that v belt pulleys follow strict standards for their groove angles, sizes, and mounting systems. For example, European pulleys use a taper bush, while American pulleys often use an expansion sleeve. These details help you pick the right v belt pulley for your job.

Component | Function |

|---|---|

Steel wires | Give strength and help transmit rotary motion and torque. |

Base rubber compound | Surrounds the wires, shapes the belt, and absorbs shocks during power transfer. |

Protective cover | Shields the rubber from heat and wear during v belt drive operation. |

The secret to a v belt pulley’s success is the V-shaped groove. This groove lets the v-belt sit deep inside the pulley, which increases the contact area. More contact means more friction, so the belt grips the pulley better. This grip stops the belt from slipping and boosts power transmission efficiency. The wedging action of the v-belt in the groove also locks it in place, even when the pulley spins fast or carries heavy loads. You see this design in action in everything from car engines to washing machines. If you want to keep your v belt pulley running smoothly, always check for proper alignment and tension. This helps you avoid slippage and keeps your v belt drive working at its best.

The V-shaped groove increases friction and grip.

More friction means less power loss and better efficiency.

The groove also helps the belt resist bending and wear.

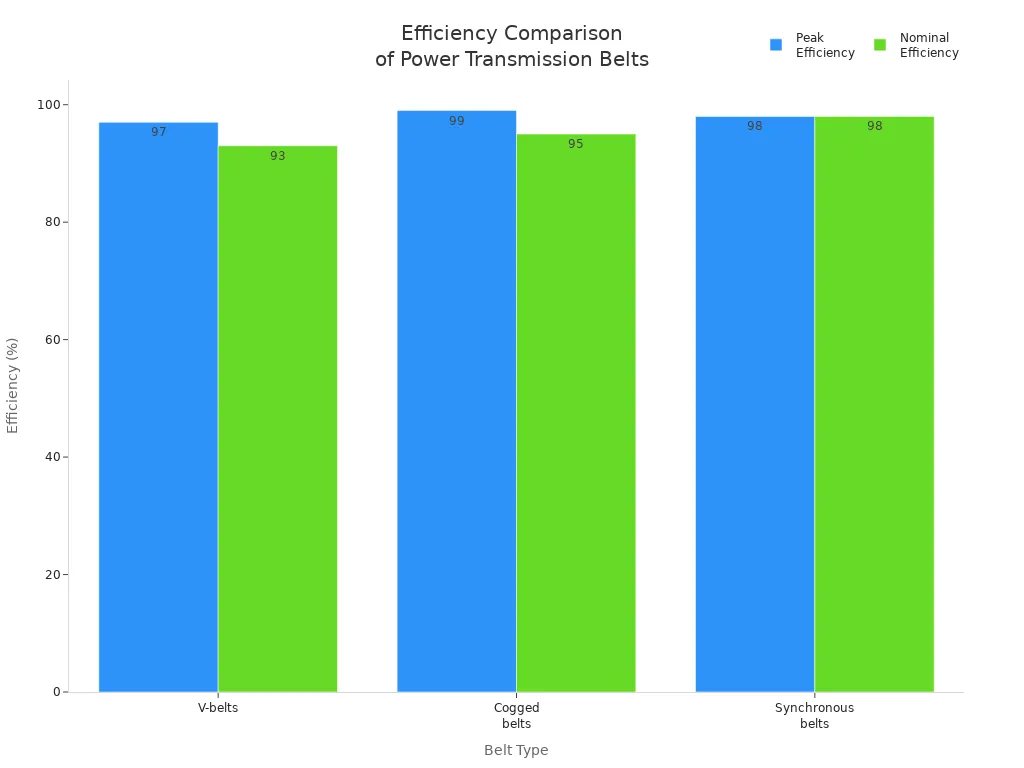

You get many benefits when you use v belt pulleys. First, v belt pulleys offer high efficiency, often reaching up to 98% when new. They work well in high-speed and high-power transmission jobs because of their strong grip. You can find v belt pulleys in cars, industrial machines, treadmills, and even sewing machines. Some v belt pulley types use cast iron for strength, while others use aluminum for lighter weight. Each material affects how the pulley handles heat, vibration, and wear. If you want your v belt pulley to last, regular v belt pulley maintenance is key. Check for wear, keep the grooves clean, and make sure the v belt fits right. When you know how to measure a v belt, you can replace it before it fails. This keeps your v belt drive system safe and reliable.

Tip: Always check your v belt pulley for proper alignment and tension. This simple step can extend the life of your v belt and improve power transmission.

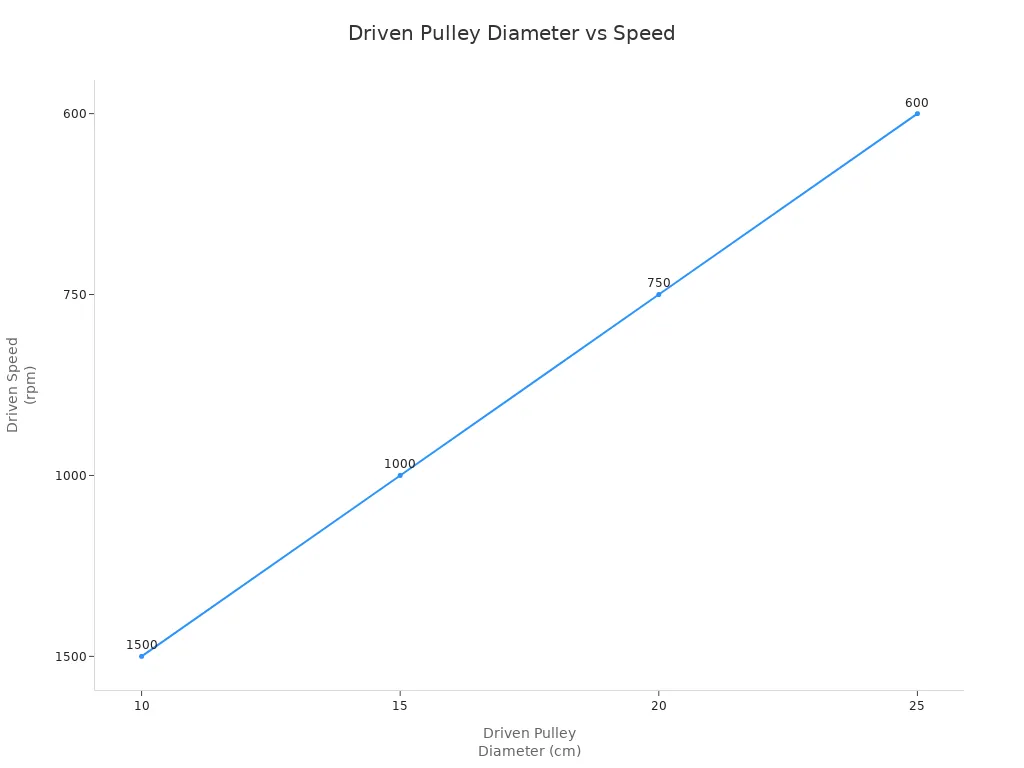

When you look at a v belt pulley system, you might wonder how changing the size of one pulley affects the speed of another. The answer is pretty simple: the size of each pulley controls how fast it spins. If you use a larger v belt pulley on the driven side, that pulley will turn slower. If you use a smaller v belt pulley, it will spin faster. This happens because the belt moves at the same speed around both pulleys, but the distance it travels on each pulley depends on the diameter.

Let’s break it down. Imagine you have two pulleys connected by a v belt. The driver pulley attaches to your motor, and the driven pulley connects to the machine you want to power. If both pulleys are the same size, they spin at the same speed. But if the driven pulley is bigger, it takes more time for the belt to go all the way around, so it spins slower. If the driven pulley is smaller, it spins faster because the belt wraps around it more quickly.

You can see this relationship in the table below:

Drive Pulley Diameter (cm) | Driven Pulley Diameter (cm) | Drive Speed (rpm) | Driven Speed (rpm) |

|---|---|---|---|

10 | 10 | 1500 | 1500 |

10 | 15 | 1500 | 1000 |

10 | 20 | 1500 | 750 |

10 | 25 | 1500 | 600 |

As the driven pulley gets larger, its speed drops. This is why you see big v belt pulleys in machines that need more torque and less speed, like conveyors or mixers. Smaller pulleys work best when you want high speed, such as in fans or alternators.

Tip: Always match your v belt pulley size to your machine’s needs. Too much speed or torque can damage your equipment or wear out your v belt faster.

You don’t have to guess how fast your v belt pulley will spin. There’s a simple formula you can use to figure it out. The speed ratio in a v belt pulley system shows how the speed of the driver pulley compares to the speed of the driven pulley. Here’s the formula:

Speed Ratio (Rs) = RPM1 / RPM2 = D2 / D1

RPM1 is the speed of the driver pulley (the one attached to the motor).

RPM2 is the speed of the driven pulley (the one attached to the machine).

D1 is the diameter of the driver pulley.

D2 is the diameter of the driven pulley.

This formula tells you that the speed ratio is the same as the ratio of the diameters, but flipped. If you make the driven pulley twice as big as the driver, it will spin at half the speed. If you swap them, the driven pulley will spin twice as fast.

You can also use this formula to find the speed of the driven pulley:

Driven Speed (RPM2) = Driver Speed (RPM1) × (D1 / D2)

This formula works for any v belt pulley system, whether you’re working with an alternator v belt pulley, a double v belt pulley, or a v belt tension pulley.

Let’s walk through a real-world example. Suppose you have a v belt motor pulley that spins at 1773 rpm and has a diameter of 6.5 inches. You want to drive a fan using a v belt pulley with a diameter of 11.5 inches. How fast will the fan spin?

First, use the formula:

Driven Speed (RPM2) = Driver Speed (RPM1) × (D1 / D2)

Plug in the numbers:

Driven Speed = 1773 × (6.5 / 11.5) Driven Speed = 1773 × 0.5652 Driven Speed ≈ 1002 rpm

So, the fan will spin at about 1002 rpm. The speed ratio is 11.5 / 6.5 = 1.77, which means the fan runs slower than the motor. This setup gives you more torque at the fan, which is great for moving heavy air.

You can also use teeth count instead of diameter if you have a v belt pulley belt with teeth. For example, if your driver pulley has 10 teeth and your driven pulley has 40 teeth, the speed ratio is 40/10 = 4:1. The driven pulley will turn one-fourth as fast as the driver.

Now, let’s talk about torque. When you use a larger v belt pulley on the driven side, you get more torque. Torque is the force that helps your machine do work. The bigger the pulley, the more leverage you have. This is why v belts and pulleys are so popular in heavy-duty machines. If you use a smaller pulley, you get less torque but more speed. Always choose your v belt pulley based on whether you need more speed or more power.

Here’s a quick summary of how pulley size affects torque and speed:

Larger driven pulley = lower speed, higher torque.

Smaller driven pulley = higher speed, lower torque.

The v-belt design helps grip the pulley and transfer more torque without slipping.

If you need more torque, use a bigger v belt pulley on the driven side.

If you need more speed, use a smaller v belt pulley.

Note: Always check your v belt and v belt pulley for wear and alignment. A worn v belt or misaligned pulley can cause slipping, reduce efficiency, and shorten the life of your v belt drive.

When you use larger v belt pulleys, you change how your machine works. A bigger pulley on the driven side will slow down the speed but give you more torque. This happens because the belt moves at the same speed, but a larger pulley takes longer to make a full turn. So, your machine runs slower, but it can handle heavier loads or tougher jobs. You might notice that the shaft spins fewer times per minute, but it feels stronger and more powerful.

Torque increases with the size of the pulley. The bigger the radius, the more force you get. If you need to move something heavy or need extra pulling power, a larger pulley helps you do that. Just remember, when you increase the size, you also ask your motor to work harder. The motor needs to provide more torque, especially when starting up or speeding up. This is a basic rule in v belt pulleys and helps you pick the right size for your needs.

Tip: If you want more power and less speed, try using a larger pulley on the driven side. It’s a simple way to boost torque without changing your whole setup.

You see larger v belt pulleys in many heavy-duty machines. They work well in conveyor belts, mixers, crushers, and big fans. These machines need more torque to move heavy parts or materials. In a v belt pulley application like a cement mixer, a larger pulley helps the drum turn slowly but with enough force to mix thick concrete.

Here are some things to keep in mind when using larger pulleys:

Make sure you have enough space. Larger pulleys take up more room.

Check the belt wrap and tension. If the pulleys are too far apart, the belt might slip.

Use strong materials like machined cast iron for better performance.

Sometimes, you need a tensioner or idler to keep the belt tight and prevent slipping.

Higher belt tension can help, but it might wear out the belt faster.

Larger v belt pulleys let you move more power, but you need to balance size, space, and belt life. Always check your setup before making changes.

When you use a smaller v belt pulley, you change how your machine works. Smaller pulleys spin faster than larger ones. If you put a small pulley on the motor side, you can reduce the output speed and boost the torque. The change depends on the ratio between the driving and driven pulleys, not just their size. For example, if you swap a 5-inch motor pulley for a 2-inch one, you create a 2.5:1 ratio. This means your speed drops, but your torque goes up by that same factor.

You can see how this works in many v belt pulley setups:

Smaller pulleys on the driver side slow down the driven equipment and increase its pulling power.

The ratio between pulley diameters decides how much speed and torque change.

A 2-inch and 4-inch pulley combo gives you the same 2:1 speed reduction as a 3-inch and 6-inch combo.

Always make sure your pulley is not smaller than the width of your v belt. This keeps your system safe and running well.

Note: Using a pulley that is too small can cause problems. You might see cracked belts, slipping, or even early belt failure. Always check your belt tension and alignment to avoid these issues.

You will find smaller v belt pulleys in many places where machines need to run fast or fit into tight spaces. These pulleys work well with rubber raw edge v-belts, which handle high speeds in compact drives. Here are some common v belt pulley application examples:

HVAC equipment, like fans and compressors

Lawn and garden machinery, such as mowers and tillers

Agricultural equipment, including water pumps and rollers

Classic A and B type v-belts, which are smaller, also show up in these machines. They help move power to parts like paddles, fans, and other light-duty tools.

But smaller pulleys come with challenges:

They reduce the contact area between the belt and pulley, which can make the belt slip or jump.

More bending and stretching can wear out the belt faster.

Higher friction can heat up the belt, causing it to crack or separate.

If you notice your belt wearing out too soon, check if your pulley is too small. Sometimes, you need to recalculate your setup or switch to a larger pulley to keep your system safe and reliable.

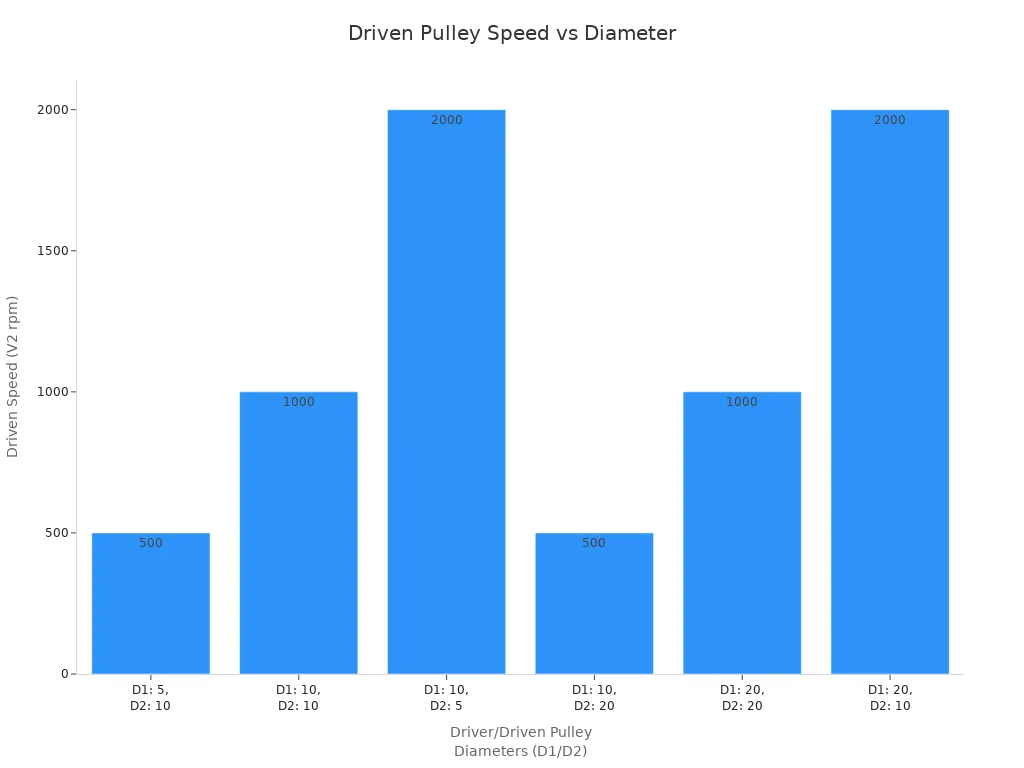

When you look at v belt pulleys, you see that size changes everything. Larger and smaller pulleys work in different ways. Here’s a table that shows how speed and torque change when you use different pulley sizes:

Driver Pulley Diameter (D1) | Driver Speed (V1 rpm) | Driven Pulley Diameter (D2) | Driven Speed (V2 rpm) | Torque Output | Typical Use Case |

|---|---|---|---|---|---|

5 | 1000 | 10 | 500 | High | Mixers, conveyors |

10 | 1000 | 10 | 1000 | Standard | General machinery |

10 | 1000 | 5 | 2000 | Low | Fans, alternators |

10 | 1000 | 20 | 500 | Very High | Crushers, heavy loads |

20 | 1000 | 20 | 1000 | Standard | Large industrial fans |

20 | 1000 | 10 | 2000 | Low | High-speed tools |

You can see that when the driven v belt pulley is larger, the speed drops but torque goes up. When the driven pulley is smaller, speed increases but torque drops. This trade-off helps you pick the right v belt pulley for your job.

Tip: Always check your speed and torque needs before you choose a v belt pulley. The right size makes your machine run better and last longer.

Picking the best v belt pulley for your setup can feel tricky, but you can break it down into simple steps. Here’s a guide to help you make the right choice:

Figure Out Your Needs

Start by asking what your machine needs. Do you want more speed or more torque? If you need high speed, go for a smaller driven v belt pulley. If you need more pulling power, pick a larger one.

Check Pulley Size and Type

Look at the diameter and type of v belt pulley. Single-groove pulleys work for simple jobs. Multi-groove or double v belt pulleys help with bigger loads or more power.

Choose the Right Material

Think about where you will use the pulley. Cast iron works well for heavy-duty jobs. Aluminum is light and good for places where weight matters. Steel gives you extra strength. For light-duty or low-cost needs, plastic might work, but it does not last as long.

Match the Belt and Groove

Make sure your v belt fits the groove of the pulley. The groove angle and width must match the v belt exactly. If they do not match, you get slipping, noise, or fast wear.

Check Alignment and Tension

Line up your v belt pulley with the motor shaft. Keep the belt tight but not too tight. Good alignment and tension help your v belt last longer and work better.

Think About Load and Speed

Check the load your machine will handle. Make sure the v belt pulley can take the weight and spin at the speed you need. If you use a v belt alternator pulley or v belt tension pulley, check the speed rating and load limits.

Look at the Environment

If your machine runs in a hot, wet, or dirty place, pick a pulley material that can handle it. Some v belt pulleys resist heat, oil, or chemicals better than others.

Follow Industry Standards

Use pulleys and v belts that meet industry standards. This helps you get the right fit and keeps your system safe. Always check the manufacturer’s guide for your v belt pulley belt and v belts and pulleys.

Note: Selecting the right v belt is not just about size. You need to look at the whole system—belt, pulley, load, and environment.

You can save time and money by avoiding these common mistakes when you pick a v belt pulley:

Using the wrong groove profile for your v belt. This causes slipping and fast wear.

Picking a pulley with the wrong number of grooves. This can lead to misalignment and machine downtime.

Choosing the wrong mounting style. Make sure you know if you need a bushing or a bored-to-size pulley.

Forgetting about the environment. If you use the wrong material, your pulley may rust or wear out too soon.

Ignoring the speed and load ratings. Overloading your v belt pulley can cause it to fail.

Always double-check your v belt, pulley size, and mounting before you order. A little planning keeps your machines running smoothly.

You’ve seen how v belt pulley size changes speed and torque. Always match your v belt pulley, v belt motor pulley, or v belt alternator pulley to your machine’s needs. The right size boosts efficiency and cuts costs. Want your v belts and pulleys to last longer?

Inspect your double v belt pulley and v belt tension pulley often.

Keep your v belt pulley belt clean and aligned.

Regular checks help you spot problems early and keep your system running strong.

A v belt pulley transfers power from your motor to other parts. It works with a v belt pulley belt and helps control speed and torque. You see v belts and pulleys in fans, mixers, and even your car’s alternator v belt pulley.

You need a double v belt pulley when your machine needs more power or you want to run two v belt pulley belts at once. This setup gives you better grip and helps your v belt motor pulley last longer.

No, you need to match your v belt tension pulley to your v belt pulley. The groove shape and size must fit your v belt pulley belt. If they do not match, your v belt alternator pulley or v belt motor pulley may slip or wear out fast.

Your v belt alternator pulley may slip if the v belt pulley belt is loose, worn, or the pulleys are not aligned. Check your v belts and pulleys for cracks or damage. Tighten the v belt tension pulley if needed.

You should check your v belts and pulleys every month. Look for cracks, wear, or loose v belt pulley belts. Clean your v belt pulley and adjust your v belt tension pulley to keep everything running smoothly.