- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

You can figure out which v-belt you have by checking its shape and reading any numbers or letters printed on it. If there are no markings, measure the length, width, and height of the belt. Using the correct v belt pulley along with the right v-belt ensures that machines operate efficiently. The right v belt pulley helps power transfer smoothly and keeps your equipment running reliably. Choosing the proper v belt pulley also saves energy and helps prevent frequent breakdowns.

When you identify and measure v-belts accurately, you can prevent them from wearing out too quickly. This reduces downtime and extends the life of your equipment. Storing v-belts in a cool, dry place can make them last up to six years.

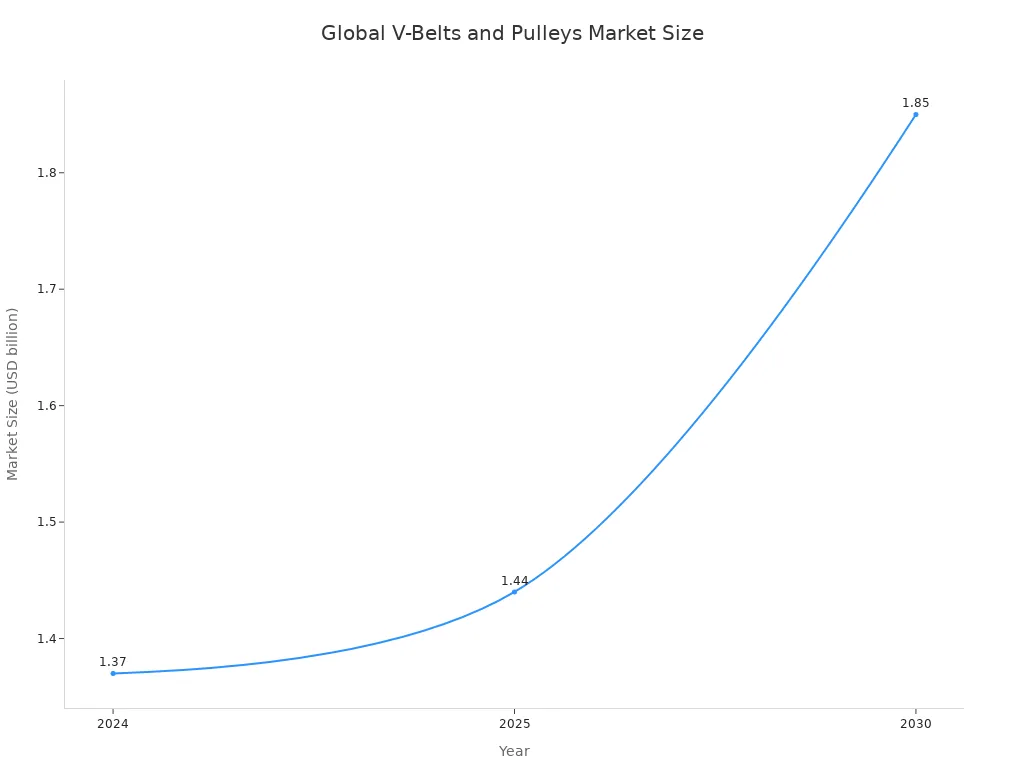

Demand for v belt pulley and v-belt solutions is growing worldwide as more industries look to automate and speed up their operations.

By selecting and maintaining the right v belt pulley, you can improve power transmission and avoid costly repairs. These simple steps help your equipment perform at its best.

Find out which V belt you have by looking at its shape or markings. If there are no markings, measure the length, width, and height. Match the V belt shape to the pulley groove. This helps make sure it fits tight and works well. Use the right tools like a cloth tape, calipers, and tension gauges. These help you measure V belts the right way and avoid mistakes. Check V belts and pulleys often for wear, damage, or if they are not lined up. This stops slipping and helps your equipment last longer. Write down the sizes and types of your V belts. If you are not sure, look at manufacturer charts or ask an expert.

A v belt pulley is a key part of many machines that use power transmission. You will find v belt pulleys in cars, factories, and even farm equipment. The main job of a v-belt pulley is to transfer power from one shaft to another using a v-belt. This system helps machines run smoothly and efficiently.

You can spot a v belt pulley by its round shape and the V-shaped grooves along its edge. These grooves match the shape of the v-belt, which helps grip the belt tightly. Most v belt pulleys are made from strong materials like cast iron, steel, or aluminum. Each material offers different benefits. Cast iron gives strength and wear resistance. Steel works well for high-speed jobs. Aluminum is light and resists rust.

A v-belt pulley comes in different types. Some have standard grooves for classic v-belts. Others, like idler pulleys, help keep the belt tight but do not transfer power. Step pulleys let you change speed by moving the belt to a different groove. You will see v belt pulleys in many industrial applications and mechanical applications.

A v belt pulley works by using the V-shaped groove to increase the contact area with the v-belt. When you fit the belt into the groove, it wedges in tightly. This wedging action boosts friction and keeps the belt from slipping. The v-belt pulley uses this grip to transfer power efficiently between shafts.

The design of the v-belt pulley helps spread tension evenly across the belt. This reduces bending and stress, making the system last longer. You get reliable power transmission, even if the pulleys are not perfectly lined up. This makes v belt pulleys a popular choice for many machines.

Tip: Always check that the groove angle and width match your v-belt. This ensures the best grip and power transfer.

You need to watch for signs of wear on your v belt pulley. Worn pulleys can cause problems with power transmission and shorten the life of your v-belt. Look for these signs:

Visible damage to the pulley, such as cracks or rough spots

Material buildup or dirt in the grooves

Uneven or excessive wear on the pulley surface

Strange noises like squeaking or rumbling during operation

Misalignment between pulleys, which can cause the belt to slip or wear out quickly

Overheating or vibration from the pulley area

If you see any of these issues, inspect your v belt pulleys right away. Regular checks and cleaning help keep your v-belt pulley system running well. Proper fit and alignment matter. They prevent slippage, reduce noise, and make sure your power transmission stays efficient.

You can identify a v-belt by looking at its shape, size, and markings. Most v-belts have a trapezoidal cross-section. This shape helps the belt wedge into the groove of the v-belt pulley. When you check a v-belt, look for the width, depth, and profile. Some v-belts have a smooth underside, while others have notches or cogs. Notched v-belts bend more easily and work better on small pulleys.

You may also see double v-belts. These have two v-belts joined together. They help share the load and last longer in tough jobs. If you see a banded belt, you know it is a double v-belt. You can spot these by the way the belts are joined side by side.

Tip: Always match the v-belt profile to the groove in your v-belt pulley. This helps prevent slipping and wear.

When you look at an alternator v belt pulley or a v belt alternator pulley, you may notice the belt is narrower or deeper. This design helps the belt handle more power in a small space. You can also find v belt tension pulleys that keep the belt tight and running smoothly.

V-belts come in several types. Each type has a special shape and use. The most common v-belt profiles include classical, narrow, notched, and double v-belts. You can use the table below to compare them:

V-Belt Type Group | Common Sizes | Visual/Design Characteristics | Usage Notes |

|---|---|---|---|

Conventional V-Belts | A, B, C, D, E | Trapezoidal cross-section; solid underside | Used in many v belts and pulleys; standard fit for most machines |

Notched/Cogged Belts | AX, BX, CX, DX | Notches on underside; flexible | Good for small v belt pulley belt drives; longer life; better for tight bends |

Narrow V-Belts | 3V, 5V, 8V, AVX... | Narrower, deeper profile; no full interchange | Used in high-power v belt motor pulley and alternator v belt pulley systems |

You can also find double v-belts, also called banded v-belts. These have two or more belts joined together. They work well in heavy-duty v belts and pulleys systems. When you see a v-belt with a wide, flat band joining two or more belts, you know it is a double v-belt.

Classical v-belts (A, B, C, D, E) have a wide, trapezoidal shape. You see them in many machines, from fans to v belt motor pulley drives.

Narrow v-belts (3V, 5V, 8V) have a deeper, steeper profile. They carry more power in less space. You often find them in v belt alternator pulley and v belt tension pulley setups.

Notched or cogged v-belts have small notches on the underside. These notches help the belt bend around small pulleys. They also reduce heat and stress.

Double v-belts are two or more v-belts joined side by side. They help share the load and last longer in tough v belts and pulleys jobs.

Note: Different v-belt profiles do not fit the same v-belt pulley. Always check the size and shape before you install a new belt.

You need to check your v-belt often for signs of wear or damage. A worn v-belt can slip, make noise, or even break. This can damage your v-belt pulley and stop your machine.

Look for these signs:

Cracks or missing pieces in the ribs along the v-belt

Frayed edges that show the inside cords

Peeling or flaking rubber

Shiny or glazed edges, which mean the belt is slipping

Oily or greasy spots on the v-belt, often from leaks near the v-belt pulley

Rubber worn down so the v-belt does not grip the v-belt pulley belt

If you see any of these problems, replace the v-belt right away. A damaged v-belt can cause the v-belt pulley to wear out faster. It can also make the v belt tension pulley work harder, which can lead to more breakdowns.

⚠️ Always turn off your machine before you check or replace a v-belt. Safety comes first.

You should also check the v-belt pulley for damage. If the grooves are worn or dirty, clean or replace the pulley. This helps your new v-belt last longer and keeps your v belts and pulleys system running smoothly.

When you use the right v-belt and keep it in good shape, you help your v-belt pulley work better. This means less downtime and fewer repairs for your machines.

When you want to identify a v-belt, start by looking for markings on the belt itself. Most v-belt manufacturers print important information right on the outer surface of the v-belt. You usually find these markings along the smooth side of the v-belt, not on the ribbed or notched side. The markings may appear as numbers, letters, or a combination of both. Sometimes, the markings fade over time, especially if the v-belt runs in a hot or dirty environment. If you cannot see the markings clearly, try cleaning the v-belt with a dry cloth.

Tip: Always check the entire length of the v-belt. Some markings repeat, but others appear only once.

You may notice that different v-belt types, such as those used in an alternator v belt pulley or a v belt motor pulley, have unique codes. These codes help you match the v-belt to the correct v belt pulley belt. If you use a double v belt pulley or a v belt tension pulley, you might see extra markings that show the belt is banded or reinforced.

Once you find the markings, you can decode the v-belt part number to learn about the belt type, length, and width. Here is a simple way to read most v-belt part numbers:

Look at the prefix or code at the start of the marking. This tells you the v-belt profile, such as A, B, 3L, or 5V. Each code matches a certain width and shape.

Check the numbers that follow the prefix. These numbers usually show the v-belt length. Some manufacturers use inches, while others use millimeters.

If the v-belt has an "X" after the letter, it means the belt is notched for better flexibility. For example, BX means a notched B-type v-belt.

Some v-belts use a datum length (Ld) in the part number. You can find the outside length (La) with a tape measure, then subtract a set value to get the datum length. For example, subtract 2 inches for type A v-belts.

Use the v-belt width and type to confirm the profile. For example, a B-type v-belt has a width of 21/32 inches and a depth of 7/16 inches.

Example Marking | Belt Type | Notched? | Length (inches) | Notes |

|---|---|---|---|---|

A42 | A | No | 42 | Classical v-belt |

BX84 | B | Yes | 84 | Notched, high flexibility |

3L300 | 3L | No | 30.0 | Fractional horsepower v-belt |

Note: Always match the decoded v-belt part number to your v belt pulley belt and v belt alternator pulley. This ensures the best fit and longest life for your v belts and pulleys.

If you cannot read the markings, measure the v-belt and compare it to standard sizes. This helps you find the right replacement for your v belt motor pulley or double v belt pulley system.

You can measure a v-belt accurately with a few simple tools. Professionals and DIY users often use these items:

Flexible measuring tape or cloth tape measure for measuring the length of the v-belt. You can also use a piece of string if you do not have a tape.

Calipers or a ruler for measuring the width (top width) and height (thickness) of the v-belt.

Pencil-type tension gauge or belt frequency meter for checking belt tension, especially if you want to measure a v-belt that has been in service for a long time.

Straightedge or laser alignment tool to check pulley alignment, which helps you get accurate measurements.

Clean, dry cloth to wipe the v-belt before measuring.

Tip: Avoid using a steel tape directly on the v-belt, as it can slip or give inaccurate results. Use a cloth tape or string for best results.

When the markings on your v-belt are missing or unreadable, you need to measure the length yourself. Follow these steps for the most accurate results:

Lay the v-belt flat on a clean surface. If the belt is broken, lay it out straight. If it is still in one piece, form it into a circle.

Wrap a cloth tape measure or a thin string around the outside of the v-belt. Keep the tape or string snug against the back of the belt, but do not stretch it.

If you use a string, mark where the ends meet, then measure the string with a ruler or steel tape.

Write down the outside circumference. This is the outside length of your v-belt.

To find the inside length (which is often the reference for classic v-belts), subtract a set amount based on the belt section:

For A section, subtract 2 inches.

For B section, subtract 3 inches.

For C section, subtract 4 inches.

For D section, subtract 5 inches.

Use this measurement to match your v-belt to the correct replacement. Always check the width and height as well.

Note: Do not measure the diameter or fold the v-belt in half to estimate the length. These methods are not accurate.

You need to measure the width and height of your v-belt to identify its profile. Here is how you do it:

Use a caliper or a ruler to measure the top width of the v-belt. Place the tool across the widest part of the belt.

Measure the height (thickness) from the flat bottom to the top of the belt.

Compare your measurements to a v-belt profile chart. This helps you find out if you have an A, B, C, D, or E section, or a notched or narrow v-belt.

Belt Section | Top Width (inches) | Height (inches) |

|---|---|---|

A | 1/2 | 5/16 |

B | 21/32 | 7/16 |

C | 7/8 | 17/32 |

D | 1-1/4 | 3/4 |

Tip: Always measure at several points along the v-belt. Worn belts may have uneven width or height.

You want your v-belt measurements to be as accurate as possible. Follow these best practices:

Always turn off and lock out your equipment before working on v-belts. Safety comes first.

Clean the v-belt and pulleys before measuring. Dirt or oil can affect your results.

Do not force or stretch the v-belt when fitting it onto pulleys for measurement. This can change the length and give you a wrong reading.

Use proper tension measurement tools, like a tension gauge or frequency meter, to check belt tension. Avoid using your thumb or guessing.

Inspect your v-belt for signs of wear, such as cracks, fraying, or glazing. If the belt looks stretched or damaged, replace it instead of measuring it for reuse.

Replace all v-belts in a set at the same time. This prevents uneven wear and keeps your v-belt pulley system running smoothly.

Keep your v-belts and pulleys clean, dry, and free from oil or grease. This helps maintain grip and measurement accuracy.

Use alignment tools to check that your pulleys are straight. Misalignment can cause uneven wear and make your measurements less reliable.

If you measure a v-belt that has been in service for a long time, rotate the system by hand at least one full turn before measuring. This helps seat the belt and gives you a more accurate reading.

Environmental factors like temperature and humidity can affect some belts. Polyurethane belts resist water and chemicals and work well in a wide temperature range. Always choose a v-belt that matches your working conditions.

⚠️ If your v-belt is worn, stretched, or damaged, do not try to reuse it. Always replace it with a new one that matches your measurements.

You can use these steps and tips for any v-belt, whether you have a v belt pulley belt, an alternator v belt pulley, a double v belt pulley, or a v belt tension pulley. Accurate measurement helps you find the right replacement and keeps your v belts and pulleys working at their best. When you measure carefully, you help your v belt motor pulley and v belt alternator pulley last longer and run more efficiently.

When you identify or measure a v-belt, you might run into some common problems. Avoiding these mistakes helps you choose the right v-belt and keeps your machines running well.

You may measure the length, width, or thickness of the v-belt incorrectly. This can lead to a poor fit.

You might overlook the rib profile. If the profile does not match, the v-belt will wear out faster.

You could ignore the construction type of the v-belt. This mistake can cause performance issues.

You may use old cross-reference charts. This often leads to picking the wrong part.

You might forget to check the needs of your machine, such as load or temperature.

Tip: Always double-check your measurements and compare them with the manufacturer’s catalog. If you feel unsure, ask for help from a professional.

You want to make sure your v-belt measurements are correct before you buy a replacement. Start by measuring the length, width, and height of the v-belt at several points. Compare your results with a v-belt profile chart. Check the rib profile and construction type. If you have doubts, try a trial installation to see if the v-belt fits and works well. You can also contact technical support or use online tools from the manufacturer. Reviewing your machine’s requirements helps you avoid mistakes.

Use this table to match your v-belt measurements with common profiles. This helps you find the right v-belt for your v belt pulley system.

Belt Section | Top Width (inches) | Height (inches) | Typical Use |

|---|---|---|---|

A | 1/2 | 5/16 | General machinery |

B | 21/32 | 7/16 | Industrial equipment |

C | 7/8 | 17/32 | Heavy-duty applications |

3V | 3/8 | 5/16 | High-speed drives |

5V | 5/8 | 17/32 | Alternator v belt pulley |

Note: Always match the v-belt profile to your v belt pulley for the best performance.

When you know which v belt pulley and v-belt you have, your machines work better. Picking the right v belt pulley and keeping the v-belt tight helps power move well. This also lowers the chance of things breaking.

You can save money and stop your machines from being down by checking your v belt pulley and v-belt often.

Write down the size of each v belt pulley and what kind of v-belt you use. This makes fixing things easier later.

Look at the quick reference table or ask experts for help by phone or email if you are not sure.

If you check your v belt pulley and v-belt often and keep good notes, they will last longer and work better.

You need to check the size and shape of your v belt pulley. Measure the groove and match it with your v belt pulley belt. Always compare your measurements with the manufacturer’s chart for v belts and pulleys.

An alternator v belt pulley usually has one groove for a single v belt alternator pulley. A double v belt pulley has two grooves. You use a double v belt pulley when you need more power or want to run two v belts and pulleys together.

You should check your v belt tension pulley every month. Look for signs of wear or looseness. A tight v belt tension pulley helps your v belt pulley system last longer and keeps your v belts and pulleys running smoothly.

No, you cannot use any v belt on a v belt motor pulley. You must match the v belt pulley belt size and profile. Using the wrong v belt can damage your v belt motor pulley and cause your v belts and pulleys to fail.

Your v belt pulley belt may slip if the v belt tension pulley is loose or if the v belt pulley grooves are dirty. Worn v belts and pulleys also cause slipping. Clean your v belt pulley and replace worn v belts and pulleys for best results.